The Brew Buddy II (BB403H-PID) is a fully functional control panel for 3-Vessel HERMS systems. It is a PID control variation of BB403H control panel. It maximizes the brewing quality while minimizing time consumption, resources, and efforts spent on building a brewing system. With the help of this control box, all-grain brewing is made easier and simpler. This control panel allows you to run the heating elements in HLT and BLK at the same time.

Two controller configuration options are offered:

2 standard PID controllers and one dual-channel thermometer: 2 x SYL-2352 and 1 x SYL-2802B

2 WIFI PID controllers and one dual-channel thermometer: 2 x AW-SYL-2352 and 1 x SYL-2802B

Note: SYL-2802B doesn't have WIFI feature.

Control Panel Features:

- Two best-selling SYL-2352/AW-SYL-2352 PID temp controllers that provide flexibility with programming for mashing and boiling. One controller monitors hot liquor temperature and the other for boil control.

- A dual-channel thermometer that monitors both the exit of mash tun and the exit of HERMS coil.

- All-in-one power meter that shows real-time voltage and amperage consumption.

- Two independently controlled 120V outlets for pumps. One is for the water pump and the other one is for the wort pump.

- Inter-locked switching system that reduces the chance of turning on the system when it is not ready.

- Independent circuit breakers for each heater and each pump.

- Independent contactors for each input and output port for extra safety protection.

- One PT100 RTD probe for Hot Liquor Tank temperature control.

- Two PT100 RTD probes for Mash Temperature monitoring (input and output of the HERMS coil).

- One PT100 RTD probe for Boil Kettle heat control.

- Flashing buzzer and alarm indicator.

- Illuminated switches for easy operation.

- Steel wall mount enclosure with a durable, black powder coated finish.

- Assembled in U.S.

Descriptions

This panel is built with some of Auber's most popular products for the beer brewing community. Different than regular version

BB403H, this control panel was powered by two SYL-2352 PID temperature controllers. The controller uses an advanced artificial intelligence-enhanced PID algorithm that can efficiently handle systems that are usually sluggish or difficult to control by a traditional PID controller. The controller will hold the temperature within a reasonable range of the default PID parameters. The auto-tune feature will improve control accuracy and stability to within one degree of accuracy. In most cases, there is no need for users to toggle the confusing PID parameters in order to get the system stabilized. Two alarm outputs can be activated by 10+ methods. All the control and setting parameters are stored in the non-volatile memory, even when the controller is powered off.

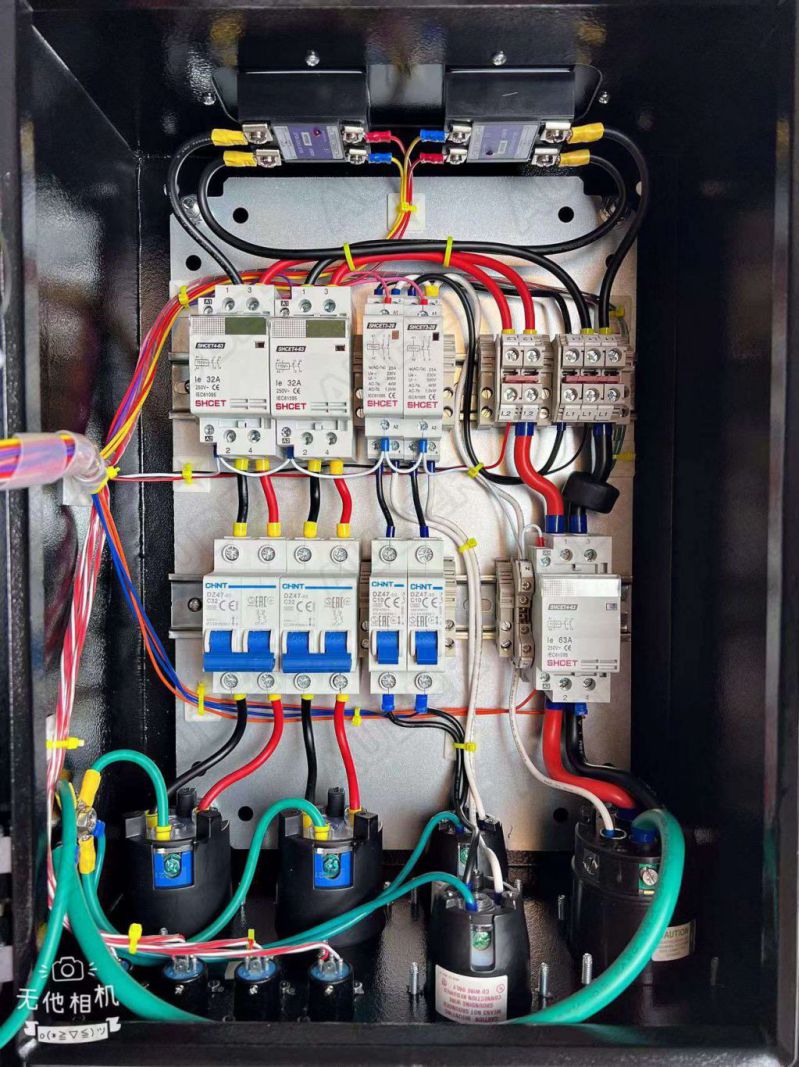

To prevent running the heater dry or having water spray all over the place, the pump control switches and heater switch are interlocked with the main power switch. Operator will not be able to power up the system unless the pump and heater are in the OFF position. One 2P 63A contactor and two 2P 32A contactors are used to control the input and output ports for added safety on North American 240VAC power lines. They will cut both the L1 and L2 lines when manually turned off. The input contactor will make the internal control panel safe when it is being opened for service. The output contactors will make the output port safe to touch when heater switches are turned off. Both the 240V AC for heater and 120VAC for pumps are protected by separate circuit breakers. If the heater or pump fails in short, these circuit breakers will trip and shut off the heater/pump to prevent further damage.

Four PT100 RTD probes and four braided cables* are included in this listing. Please select the model number of your preferred probe in the “RTD Probe Option” for each brew kettle. If you want to install the probe on the wall of the tank, the 2 inch long, weldless fitting probe,

PT100-L50M14, is the most common one to use. If you want to insert the probe in the circulation through a Tee connection, the 1.5 inch long, with ½ NPT thread mounting,

PT100-L401/2NPT, is the most common probe to use. Please leave a note for the

other probe part number you need.

*: 12ft

silicone braided cable is included in this kit. We will pick random colors for you by default; if you have a preference, please leave a message during checkout. If you order four probes in this listing, four silicone braided cables will be included. If you order three probes or less, we will include the same qty of cables in your package.

Specifications

| Heater Control Output |

30A, 240VAC maximum. NEMA L6-30R Connector. |

| Pump Control Output |

10A, 120VAC maximum. NEMA L5-15R socket. |

| Input Connection |

50A, four conductors. CS6375 Connector. |

| Sensor |

Pt100 RTD sensor, XLR connector. |

| Circuit Breaker |

(2) 32A 2-pole and (1) 10A 1-pole. |

| Temperature Controller |

Auber SYL-2352 |

| Thermometer |

Auber SYL-2802 |

| Dimension (W x H x D) |

16 x 12 x 8 inch (40 x 30 x 20 cm) |

| Weight |

28 lb (12.7 kg) |

| Warranty |

One (1) year limited warranty. See here for details. |

Notes:

1) This system is designed for 240V AC North America power lines that require four lines power connection (L1, L2, N and G). All the input/output connections are NEMA standard type.

2) Although the system is protected with circuit breakers, it is recommended to hook up this system to a GFCI or Earth Leak breaker protected power line, because water is involved in the brewing equipment.

3) We also provide a DIY kit of components for this control panel, please see

here.

4)

Input power cords are not included because each user may have different hook up requirement in terms of cable length and connection type. This panel uses CS6375 (male) receptacle as its power inlet. To power this panel, a power cord with CS6364 (female) connector is required (to match with CS6375 receptacle). We offer CS6364 connector as an option.

6) Lead time is about 3-4 business days. Please

contact us if you have any questions.

7) If you need a different probe, please choose either probe option and leave a note during the checkout, for the probe part number you want. Or you can send us an email after you place the order. We will confirm and let you know.

Figure 1. Front View of the Control Panel.

Figure 2. Bottom View of the Control Panel.

Figure 3. Internal View of the Control Panel.

Figure 4. CS6364 Power Input Connector (Optional).

This product was added to our catalog on Thursday 11 May, 2023.